Prefabricated interior wallboard, as a component of industrial residential prefabrication technology, is more and more widely used in various fields. It can ensure the quality of wallboard, increase production, improve installation efficiency, reduce labor, reduce wet operation, reduce construction waste, reduce urban environmental pollution, increase indoor use area and so on. A strong advantage is the development trend of building materials.

“Lushi Mould was invented by Mr. Lushi, founder of Bentel Mei (Huizhou) Building Materials Co., Ltd. in 2003. The "Lucas Formwork" wallboard production equipment is currently the first in the country. Formwork casting is the only concrete wallboard casting mode in Hong Kong and even in the world.

The production material of prefabricated wallboard is composed of cement, fine stone, sand, water, additives and reinforcing bar. The six kinds of materials are stirred into concrete fluid to form and solidify.

Wallboard production is a complex and huge system engineering, it is composed of mixing system, transportation system, mold system (Lushi vertical mold), lifting and disassembly system, hydropower and maintenance system.

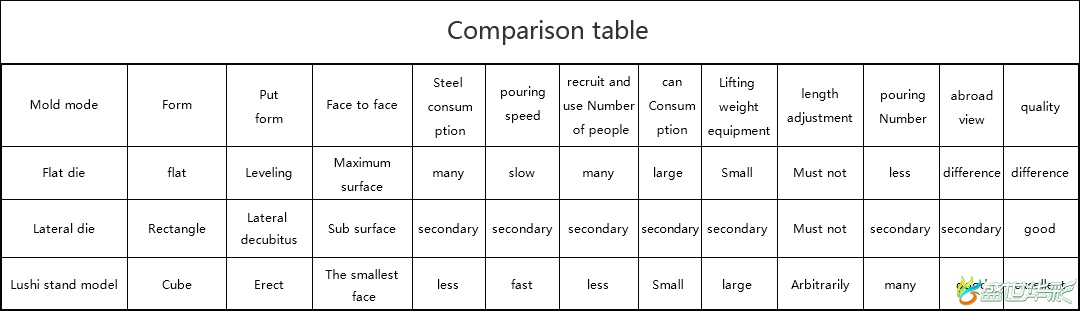

There are many kinds of molds for wall panels in China's building materials market. They can be divided into three types: flat mold, side mold and vertical mold according to the mold making, placing and pouring forms. Their respective characteristics are shown in the comparison table.

- 1Characteristics of flat dieTraditional manufacturing process, it is composed of bottom mold, edge touch, pipe rack and connectors, low technical requirements, a general construction worker can be on duty after a little training, production capacity is very low, assembly and disassembly of the workload is large, a set of molds can only produce one piece of wallboard, so it takes up a large area, it is difficult to ensure the smoothness and smoothness of artificial face collection. 2Characteristics of side dieRecent development of production technology, from the bottom mold, edge touch, horizontal partition, pipe rack, pipe rack power system and pipe rack placing operation rack, side mold system in the assembly and disassembly of mold, pouring concrete, pipe pulling and other needs a certain technology, due to the use of more machinery, mold equipment, production has been greatly improved, each time can be. In order to produce 8-10 panels, only plain concrete can be poured, and the slump or mobility of concrete is greater. Due to the high requirement for equipment due to horizontal lateral die drawing, the side die process saves a certain operating space compared with the flat die. 3Characteristics of formworkAs the name implies, the wallboard will be erected and poured, "Lushi Form" is the production of wallboard in this way, it is the world's most advanced production technology and equipment, make up for the shortcomings of the flat mold and side mold, in the use of labor, time-saving, energy-saving, quality and many other aspects of the various indicators of the mold are prominent.

-

Most of the early precast wall panels use flat die and side die, and the production capacity is 1 to 10 units per time. Flat mold is a single piece of board installed and dismantled, pouring only one wall slab at a time, and the largest surface is the surface. Side mold is recumbent pouring, one time forming 8 - 10 wallboard, horizontal drawing mold, but it is difficult to ensure the level of pipe rack.

The company has been engaged in the production of prefabricated components since the founding of the factory. The "Lushi Form" has solved the common shortcomings of the plane mold and the side mold, and has made the wallboard production fast with a large amount of pouring. It can produce 22 wallboards at the same time. It saves manpower, saves time, saves space, has quick turnover and less waste. Because the finish is the smallest surface of the sheet metal, the shape is smooth and beautiful, and the quality is guaranteed. It belongs to semi-mechanized production. The drawback of the vertical die is also the advantage of the equipment. It needs large lifting equipment.

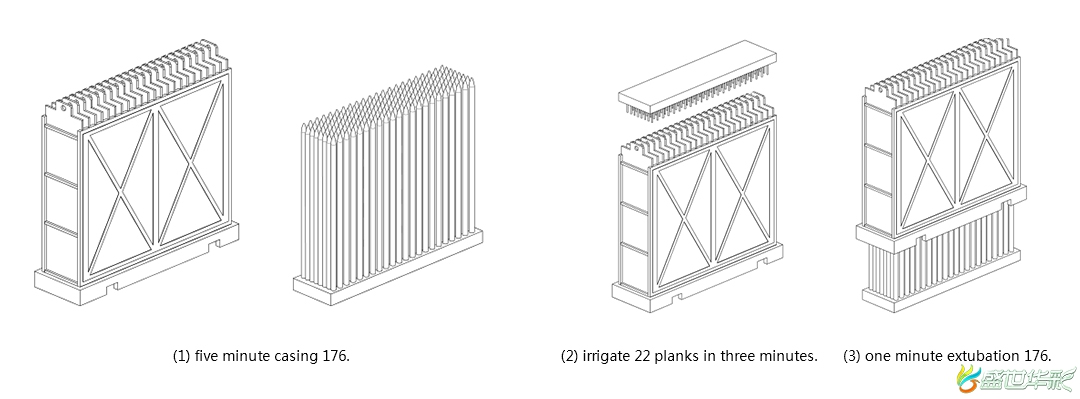

The basic structure of "Lushi Die" is shown in the schematic diagram of the die. The "Bear Embrace" is one of the important characteristics of the design of the die. The die part of the vertical die is composed of two side dies and one bottom die, while touching, it can fix 21 partitions at the same time. The pipe rack is made up of 176 steel pipes and chassis. The structural side of the bottom die and the edge touch is composed of steel beam (channel steel, angle steel), steel plate and high-strength bolt through structural design and calculation, which are assembled under the stress produced in the process of pouring, drawing, lifting and disassembly. The strength and deflection of each rod and steel plate in the die conform to the current steel structure specifications, and the die as a whole. Stability is also safe.

"Lushi Formwork" belongs to the production mode of vertical group formwork. There are 22 wallboards and 176 pipe racks in the mold. After the initial setting of concrete (solidification time), they are separated by two times. The "pull-up" demoulding method is adopted. Therefore, the pull-out force must overcome the resultant force of the frictional resistance of pipe rack, partition board and concrete.

Mechanical formula for uplift resistanceF pull over (W mixed +W mode +F rub) x F move

Among them: F pull - the power of crane four W mixed concrete concrete wall panels W mode --W bottom mode +W side touch + sigma baffle F --F pipe rack +F floor +F parapet +F diaphragm F dynamic dynamic load factor ⑥

Production and Application

Production and Application

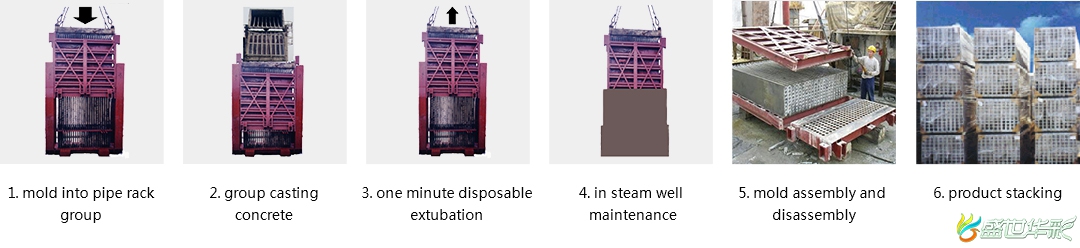

The production process of the wallboard is as follows: mixing concrete according to mixing ratio, conveying concrete by conveying equipment, pouring concrete into the "Lucas Formwork" - - pouring while vibrating (22 wallboards can be poured in 3 minutes, see Figure 2 of the mold) - - modifying one of the smallest exteriors - - - the concrete in the vertical mold reaches the drawing strength of 7 - - - pulling out. Separation of mold and pipe rack (pull-up die completed within 1 minute, see mold diagram 3) - - transporting mold inner wall board to steam pit maintenance - - - wall board to achieve design strength - - - demolition of "Lushi vertical mold" mold - - - wall board production completed - - - cleaning mold and partition - - - reassembly "Lushi vertical mold" - - hanging back to pit groove - - - mold sleeve tube Rack (5 minutes to complete, see chart 1) - recycling.

The production system of "Lushi Formwork" is a new type of strip production system, which takes reinforced concrete as raw material, vertical formwork and vertical pipe as mold, and all production processes of a large group of hollow strips are synchronized. The system is the core part of the whole production process of wallboard, and other systems. It is the auxiliary part of pouring wallboard around the vertical mold.

Because the prefabricated wallboard is not affected by humidity or dryness and other environmental factors, the wallboard produced by the vertical mold is widely used in residential, hotel, school non-load-bearing wall. Since its invention 15 years ago, it has produced nearly 10 million hectares of wallboard with a pass rate of over 99.9%. It has been used in more than 100 projects in Hong Kong.

Due to the inherent characteristics of the interior panel, the strips produced are hollow, light and high strength, comprehensive in physical properties, accurate in size, flat and flawless in surface, convenient for site installation, easy to operate, fast in speed, and 100% less plastering. As filling materials, they are more and more widely used.

Adjust the concrete strength and reinforcement content to produce partitions, wall panels, load-bearing wall panels and floors. That is to change the space between the diaphragms in the mold, increase the thickness of the wallboard, increase the stress surface of the concrete, and change the structure of the wallboard.